Table Of Contents For This Page

It’s not easy to cover all aspects of custom door handles, so we’ve prepared a wealth of information on this page for you to delve into. To ensure that you can quickly find the information you are looking for, we have prepared this content catalog, which when clicked on will take you to the appropriate location.

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 1

When selecting door handles for any project, whether residential or commercial, it’s important to consider key factors like functionality, durability, and aesthetics. The right door handle not only enhances the look of a space but also ensures lasting performance. To make an informed decision, it’s essential to explore different types of door handles, the materials they are made of, the available colors and finishes, and the certifications that guarantee quality.

By types

Lever Handle

Door knob

Pull Handle

By material

Aluminum

Zinc

Brass

Stainless steel

Steel

Plastic

Ceramic

Wood

By finish

Antique Bronze

Satin Brass

Grey

Matt Black

Polished Chrome

PVD

Satin Nickel

Antique Brass

Antique Copper

By standard

En1906

DIN18257

By Material

Aluminum door handle production process

For the aluminum handles, we use ADC12 die-casting ingots of environmentally friendly alloy, which are first heated and melted in a furnace to ensure that the aluminum liquid reaches a suitable casting temperature.

The molten aluminum is then poured into a pre-designed steel mould, which is cooled to solidify and form the aluminum. After forming, the aluminum handles often have burrs or excess edges, which need to be deburred by tools such as grinding wheels and sandpaper to ensure a smooth and even surface. And according to the design requirements, the aluminum handles are mechanically processed by drilling, tapping, and cutting to meet the specific installation and usage requirements.

Finally, through electroplating, the aluminum handles are plated with a metallic coating, such as gold, silver, bright chrome, etc., to increase their aesthetics and corrosion resistance.

Zinc Door Handle

Zinc alloy handles usually include zinc ingots, aluminium and other alloying elements, which are heated to a molten state in a high-temperature furnace at a temperature generally above the melting point of the zinc alloy so that they are well mixed.

The molten zinc alloy is injected into the mould of the die-casting machine and fills the mould cavity under pressure to form the initial handle shape. After casting, the semi-finished handle needs to be cooled and cured, and then it is processed by separating the material and removing excess parts such as risers and trimmings.

The semi-finished products are further processed using drilling machines, drilling and tapping machines and other equipment, such as punching and trimming, to meet the product design requirements. The machined handles are polished to improve their surface finish and aesthetics. In order to enhance the corrosion resistance and aesthetics of the handle, it is usually plated. The plating layer can be chromium, nickel and other metals, forming a uniform layer on the surface of the handle through the plating process.

Brass Door Handle

The raw material for brass handles is usually purple copper or brass. The copper plate is put into a stamping machine and stamped through a mold to form the initial shape of the handle. During the stamping process, necessary corrections and adjustments need to be made to ensure the accuracy and consistency of the shape. In addition to stamping and forming, copper handles may also be formed using a forging process. The forging process uses forging equipment to forge copper into the desired shape.

The parts of the handle are then milled to further trim and polish the shape to ensure that the accuracy and dimensions of each part meet the design requirements. Drilling is carried out on the handles for the subsequent installation of fixings such as screws or bolts. Grinding and polishing the surface of the brass handles to remove the burrs and uneven parts of the surface, so that the surface is smooth, bright and does not hurt the hand.

Finally, in order to protect the surface of the handles from corrosion and oxidation, they are usually plated. The plating layer can be chromium, nickel and other metals, through the plating process on the surface of the handles to form a layer of uniform plating, to improve the corrosion resistance and aesthetics of the product.

Stainless steel Door Handle

Stainless steel handles have various production processes, mainly including stretching process, die-casting process, injection moulding process, turning process and stamping process.

- Stretching process: the use of cold rolled sheet material, through continuous casting, rolling, billet heat treatment and other multi-processes, and then through the moulding, cold drawing, heat treatment and other multi-processes made.

- Die casting process: the molten stainless steel is pressed into the mould cavity through the metal mould and cooled and shaped for a certain period of time.

- Injection moulding process: The molten raw material is injected into the mould through the injection moulding machine and cooled and shaped after a certain time.

- Stamping process: the raw material is punched, cut, bent, stretched and other multi-processes through the mould to make handle products.

Steel Door Handle

According to the design requirements of the iron handles and the use environment, choose suitable iron materials, such as ordinary iron, stainless steel and so on. Then according to the design drawings, use the cutting machine, shear machine and other equipment to cut the iron material into the required shape and size.

For the part of the iron handle that needs to be bent, it can be bent and shaped by bending machine, mould pressing and other methods; for the iron handle that consists of multiple parts, it needs to be welded and assembled. The welded iron handle is polished to remove the uneven parts such as weld residual height and burr, so as to make the surface smooth and even.

Next, the iron material is descaled to prevent rust from affecting the beauty and service life. According to the design requirements, the iron handles are painted or electroplated to give them the required colour and gloss.

Plastic Door Handle

Choose suitable plastic materials, such as ABS, PP, etc., and dry and preheat the plastic granules to ensure that the materials have good fluidity and formability during the injection moulding process. The treated plastic granules are put into the barrel of the injection moulding machine and injected into the mould after high temperature and pressure treatment. The plastic is cooled and hardened in the mould to form plastic handles with specific shapes and sizes. After the plastic handle has cooled and hardened, the product is removed from the mould.

The injection-moulded plastic handles are then deburred to remove excess parts produced by the mould parting lines, etc. The surface of the plastic handle is sanded and polished to make the surface smoother and flatter.

Finally, according to the customer’s demand, the plastic handle is sprayed with paint or plated.

According to the design requirements, glaze the blanks after firing. The choice of glaze and glazing method will affect the appearance and performance of the final product. The glazed blanks are fed into the kiln again for glaze firing. During glaze firing, the glaze melts and adheres to the surface of the billet, forming a smooth, shiny glaze layer.

After glaze firing, the ceramic handles may need to be sanded, polished and other post-processing to improve the aesthetics and feel of the product. Perform quality inspection on finished products, including appearance inspection, size measurement, and function test. Ensure the products meet the design requirements and quality standards.

Ceramic Door Handle

Select raw materials suitable for making ceramic handles, such as kaolin, quartz and feldspar. Crush, grind and sieve the selected raw materials to obtain uniform and fine powder.

There are various moulding processes for ceramic handles, the common ones are slurry moulding, billet pulling moulding and printing billet moulding.

Slurry moulding: Clean the inside and outside of the mould to prevent impurities from mixing in. Inject the slurry into the mould, and wait for the slurry to harden in the mould. When the blank hardens to a certain degree, open the mould and remove the blank for trimming.

Pulling and moulding: practice the clay material evenly and knead it into suitable sized pieces. Place the lumps on a rotating wheel and pull the initial shape of the handle by hand according to the design. The blank is further trimmed on the machine wheel and the attachment part of the handle is glued.

Forming of the printed blanks: the clay cakes or strips are placed in the mould and the initial shape of the handle is formed by pressing. The blank is removed and trimmed after it has hardened.

The moulded blanks are placed in a drying chamber to remove moisture from the blanks. The dried blanks are fed into the kiln for firing. The purpose of firing is to give the blanks a certain strength and hardness for subsequent processing and decoration.

wood handle

The selection of wood for wood handles is crucial, as it directly affects the quality and appearance of the product. Common woods include walnut, pine and oak, which are popular for their hard texture and beautiful grain.

Firstly, the selected wood is truncated according to the design requirements, and then the wood is cut into preliminary shapes and sizes using equipment such as band saws and multi-blade saws. The cut timber is straightened by means of a straightening mechanism to bring its condition in line with the preset attitude for subsequent processing.

The timber is finely milled and sanded using equipment such as milling machines and grinders to remove burrs and uneven parts of the surface, so as to make the surface of the wooden handles smooth and delicate. According to the design needs, drill holes in the wood handle to install screws or other connectors. After drilling, cleaning is required to ensure that no wood chips remain in the holes.

For wooden handles that require a handle section, the handle also needs to be individually fabricated and fitted. This usually involves cutting, sanding, and bending to ensure that the handle fits snugly and ergonomically into the main part.

The machined parts of the wooden handle are assembled to ensure that the connection is strong and free from looseness. In order to enhance the durability and aesthetics of wooden handles, surface treatment is usually required. Common finishes include lacquering, staining and polishing.

By standard

Standards and certifications for door handles, as part of the building hardware, ensure the quality, safety and performance of the product. Different countries and regions have different standards and certification organisations, the following are some of the main international standards and certifications for door handles

EN1906

EN 1906 is a standard specifically for door handles and covers the performance requirements for durability, safety and functionality of door handles.

Requirements:

- Durability: Door handles need to be tested for durability to confirm their reliability in long-term use. This includes the number of operations, wear resistance tests, etc.

- Safety: The standard specifies safety requirements for door handles in different use environments, such as protection against unintentional operation or guarding design.

- Functionality: This includes the operating strength, comfort and adaptability of door handles to different door thicknesses and types.

Material: the material of door handles should meet the performance requirements such as corrosion resistance and anti-aging.

DIN 18257

DIN 18257 and DIN 18273 are two different standards developed by the German Organisation for Standardisation (DIN). They both deal with door handles, door locks and related accessories, but each focuses on different technical requirements and applications.

Standard content:

- Focus: DIN 18257 is mainly concerned with the technical requirements for door handles, door locks and related accessories, including durability, strength and corrosion resistance.

- Application scope: covers various technical requirements and test methods for door handles and locks, which are used to ensure the safety and long-term reliability of these products in actual use.

- Technical requirements: including durability test, corrosion resistance test, etc. for door handles and locks.

Classification by durability rating:

- Class 1: Suitable for low-frequency use environments, e.g., residential interior doors. Requires lower durability.

- Class 2: Suitable for environments with medium frequency of use, e.g. office doors. Higher durability and security are required.

- Class 3: Suitable for environments with a high frequency of use, such as doors in commercial buildings or public spaces. Requires highest durability and security.

Chapter 2

Full Solutions From UMAY Custom Door Handle

20+ colors available

At UMAY, we offer an extensive range of color finishes for door handles, ensuring that they complement any interior or exterior design. Our finishes include popular choices like chrome, nickel, satin nickel, antique bronze, antique copper, gold, black, white, silver, and graphite. These finishes provide not only aesthetic appeal but also durability, withstanding wear and tear while maintaining their vibrant look over time.

If you have specific color requirements, we can go a step further. You can provide us with a RAL color number, and our team of professional technicians, highly skilled in electroplating and painting, will match the exact shade you need. This level of customization ensures that your project’s hardware blends seamlessly with the overall design concept, whether it’s for residential, commercial, or industrial use. At UMAY, we combine precision, quality, and customization to meet all your door handle finishing needs.

antique bronze

satin brass

Grey

Matt black

Polished chrome

pvd

satin nickel

antique brass

antique copper

Various combinations

At UMAY, we provide a wide selection of over 10 types of rosettes, designed to suit various style preferences and door handle applications. Whether you’re looking for a minimalist modern design or a more traditional, classic look, we have the perfect rosette to complement your project’s aesthetic.

Each rosette is compatible with over 1,000 different handle designs, offering a vast range of combinations to meet any specific architectural or interior design need. This flexibility allows you to mix and match handles and rosettes to create a unique, custom look that aligns perfectly with your vision.

Our rosettes come in a variety of shapes, including round, square, and rectangular, and are available in multiple finishes such as chrome, nickel, matte black, and brushed brass. This ensures that you can find the right finish to match both the door style and the overall décor.

With our range of high-quality rosettes and handles, you’ll have the freedom to tailor your door hardware exactly to your taste and project requirements, ensuring a cohesive and stylish final result.

ODM support

At UMAY, we understand that every project is unique, and sometimes, the perfect handle doesn’t exist—until you create it. If you have a specific design concept or want to develop your own custom handle style, we are here to bring your vision to life. Simply share your ideas with us, whether it’s a sketch, a reference image, or just a creative thought, and our experienced design team will work closely with you to turn it into a reality.

What sets us apart is our commitment to ensuring your complete satisfaction. As part of our custom design process, we offer free 3D-printed prototypes. This allows you to physically see and feel the handle design before moving into full production. You can make adjustments, refine the details, and perfect the design until it meets your exact expectations. We won’t proceed with manufacturing until you are 100% satisfied with the final prototype.

With our professional support and cutting-edge technology, creating a one-of-a-kind door handle that reflects your style and project needs has never been easier. From concept to completion, we’re here to help you design something truly special.

customized lower rosette

At UMAY, we offer a diverse range of lower rosettes to cater to various functional and aesthetic needs. Our lower rosettes are available in multiple styles, including cylinder hole, keyhole, and knob configurations, ensuring they meet the specific security and design requirements of your project. Whether you are looking for a classic keyhole design for traditional locks or a sleek cylinder hole for modern locking systems, we have the perfect option for you.

In addition to our standard offerings, our lower rosettes are fully customizable. If you have specific dimensions, shapes, or finishes in mind, we can work closely with you to design and manufacture a lower rosette that fits your exact specifications. This means you can create a seamless match between the lower rosette and the handle style, ensuring a cohesive and polished look for any door.

Whether it’s for residential, commercial, or industrial projects, our lower rosettes are designed to complement and enhance the door hardware, while providing reliable performance and long-lasting durability. From custom finishes like matte black, satin nickel, or antique brass, to tailored shapes and sizes, we can bring your vision to life with precision and quality.

laser logo on handles

At UMAY, we offer laser engraving services to help you customize door handles with your brand’s logo, adding a unique and professional touch to your hardware. Whether you’re a door manufacturer, hardware brand, or importer, adding your logo to the handles not only enhances brand visibility but also elevates the overall aesthetic of your product line.

The process is simple and efficient. All you need to do is provide us with a high-definition image of your logo, and our factory will precisely laser engrave it onto the handles. We use advanced laser technology to ensure the engraving is crisp, clean, and durable, maintaining its clarity even with long-term use.

Before moving forward with mass production, we will send you a sample of the laser-engraved handle for your review and approval. This ensures that every detail of your logo meets your expectations, allowing you to make any adjustments if necessary. Once you are completely satisfied with the result, we will proceed with the full production, guaranteeing that your custom logo is applied consistently across all handles.

With our expertise and attention to detail, you can confidently offer branded door hardware that reflects the quality and identity of your company.

Customized packages

At UMAY, we provide a wide variety of packaging options to ensure your products are not only protected but also presented in a way that reflects your brand’s quality. Our packaging solutions include color boxes, blister packaging, magnetic boxes, and hanging cardboard displays, all designed to enhance the product’s appeal and functionality.

Whether you’re looking for sleek and sophisticated packaging for high-end hardware or practical, durable options for bulk products, we’ve got you covered. Simply share your packaging requirements with our experienced designers, and they will work closely with you to create a custom solution that aligns with your branding and project goals. From material selection to design details, we ensure that your packaging meets your exact specifications and exceeds your expectations.

With our tailored approach, your products will stand out on the shelves, delivering not only functionality but also a premium unboxing experience.

Chapter 3

What Are Door Handle Used For

Handles are used in a wide and varied range of applications as key components for connecting and operating doors, drawers, cabinets and other objects.

Wooden Door

Handle materials and features suitable for wooden doors:

Wood handle

- Natural texture

- Eco-friendly and healthy

- Easy collocation

Metal handles

- Sturdy and durable

- Easy to clean

- Beautiful and generous

Plastic handle

- Low cost

- Colourful

- Lightweight and easy to install

Ceramic Handle

- Elegant and beautiful

- Corrosion resistant

Glass Door

Handle materials and features suitable for glass doors:

Stainless steel handle

- Bright and clean appearance

- Lightweight quality

- Resistant to corrosion and wear

Aluminum handle

- Dexterous

- Long life

- Good external surface and decorative effect

Brass handle

- Beautiful appearance

- Rust and corrosion resistant

Sliding Door

Handle materials and features suitable for sliding doors:

Stainless steel handle

- Bright and clean appearance

- Resistant to corrosion and wear

Aluminum handle

- Dexterous

- Long life

- Good external surface and decorative effect

- Corrosion resistance

Zinc handle

- Can be made into a variety of complex shapes and patterns

- Corrosion and wear resistance

Plastic handle

- Lightweight, attractive and cost-effective

Aluminum Door

Handle materials and features suitable for aluminum doors:

Stainless steel handle

- Bright and clean appearance

- Lightweight quality

- Resistant to corrosion and wear

Aluminum handle

- Dexterous

- Long life

- Good external surface and decorative effect

Zinc handle

- Can be made into a variety of complex shapes and patterns

- High hardness and wear resistance

Armored Door

Handle materials and features suitable for armored doors:

Stainless steel handle

- Bright and clean appearance

- Lightweight quality

- Resistant to corrosion and wear

Aluminum handle

- Antioxidant property

- Good external surface and decorative effect

Zinc handle

- Can be made into a variety of complex shapes and patterns

- High hardness and wear resistance

Brass handle

- Anti-theft

- Decorative

Cabinet Door

Handle materials and features suitable for cabinet doors:

Stainless steel handle

- Bright and clean appearance

- Lightweight quality

- Resistant to corrosion and wear

Metal handles

- Sturdy and durable

- Easy to clean

- Beautiful and generous

barn door

Handle materials and features suitable for barn doors:

Stainless steel handle

- Bright and clean appearance

- Lightweight quality

- Resistant to corrosion and wear

Metal handles

- Sturdy and durable

- Easy to clean

- Beautiful and generous

interior door

Handle materials and features suitable for interior doors:

Wood handle

- Natural texture

- Eco-friendly and healthy

- Easy collocation

Metal handles

- Sturdy and durable

- Easy to clean

- Beautiful and generous

Plastic handle

- Low cost

- Colourful

- Lightweight and easy to install

Ceramic Handle

- Elegant and beautiful

- Corrosion resistant

Folding Door

Handle materials and features suitable for folding doors:

Stainless steel handle

- Bright and clean appearance

- Lightweight quality

- Resistant to corrosion and wear

Metal handles

- Sturdy and durable

- Easy to clean

- Beautiful and generous

Chapter 4

Learn Door Handles

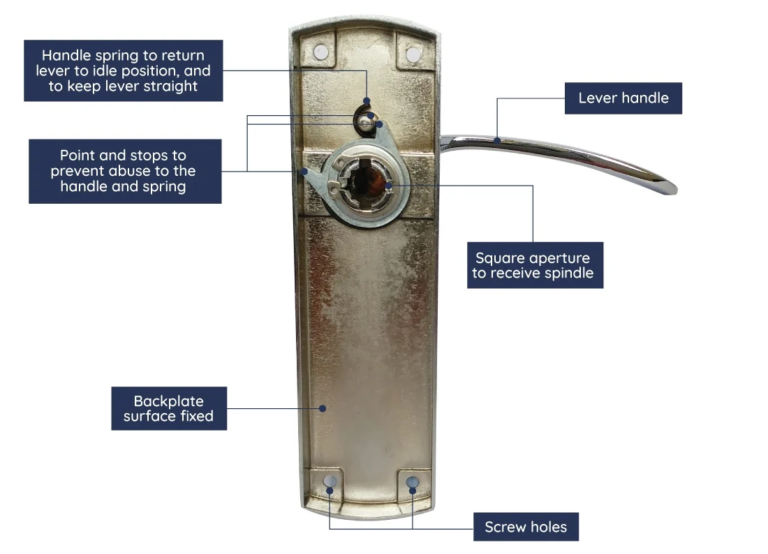

Components of a handle:

Each part supports customization with different materials and various colors available.

- Handle Body: This is the part that comes into direct contact and is used to operate the door opening and closing. It is usually made of metal (e.g. zinc alloy, stainless steel, copper, etc.), plastic, ceramic, or wood and is finished to enhance aesthetics and durability. The shape and size of the handle body can be designed to suit the type and style of door.

- Fixing base: The fixing base is the key part that connects the handle body to the door panel. It usually contains some screw holes or mounting slots for fixing the handle to the door. The material and strength of the fixing base is essential to ensure the stability and security of the handle.

- Connecting rods/transmissions (for some types): In some door handle designs, especially those that are directly connected to the door locking mechanism, connecting rods or transmissions may be included. These components are responsible for transmitting the rotational movement of the handle to the internal mechanism of the door lock, which opens and closes the door.

- Decorative pieces/cover plates: To enhance aesthetics and protect the internal mechanisms, some door handles are also equipped with decorative pieces or cover plates. These components can cover exposed parts such as fixing screws, connecting rods, etc., making the overall look of the door handle neater and more high-end.

- Mounting accessories: These include screws, nuts, spacers, etc., which are used to secure the door handle to the door. The quality and correct installation of these fittings is essential to ensure the stability and security of the door handle.

1. Panel body

- Function: As the basic support structure of the panel handle, it is usually fixed and connected with the surface of the equipment or furniture.

- Characteristics: The material, shape and size of the panel body will be designed according to specific needs to ensure its stability and aesthetics.

2. Handle Body

- Function: The part for the user to hold and operate, usually with a comfortable grip and ergonomic design.

- Characteristics: The handle body can be designed in various shapes and materials, such as round, square, curved, etc., as well as metal, plastic, wood and other materials, to meet different needs and aesthetic preferences.

3. Connector

- Function: To connect the handle body and panel body firmly together to ensure the stability and durability of the handle.

- Characteristics: The connectors may include fasteners such as screws, nuts, rivets, etc., or they may be connected by clips or welding.

4. Drive mechanism (some complex designs)

- Function: In panel handles that require special functions (e.g., automatic locking, angle adjustment, etc.), the transmission mechanism is responsible for converting the user’s operation into the corresponding mechanical movement.

- Characteristics: The transmission mechanism may include mechanical elements such as gears, levers, springs, etc., as well as the corresponding transmission path and transmission ratio design.

Handle Panel: This is the part that the user comes into direct contact with and is usually designed to be smooth, easy to grip and ergonomic. The material, shape, size and finish of the panel are customised to suit the environment in which it will be used and personal preferences.

Mounting Base Plate or Bracket: This component is used to secure the pull to a door, window, drawer or other piece of furniture. It is usually made of stainless steel or other sturdy materials to ensure stability and durability. The design of the mounting base plate or bracket may also be adjusted depending on how the pull is mounted and the material of the door/furniture.

Connectors: these components are used to connect the pull handle panel to the mounting base plate or bracket. They may include screws, nuts, spacers, etc. and are used to achieve tightness and stability of the pull handle. The quality and selection of connectors can have a significant impact on the overall performance and appearance of the pull.

Decorative pieces or accessories (if any): In some designs, stainless steel handles may also include decorative pieces or accessories such as adhesive rings, anti-slip pads, etc. These components can enhance the functionality (e.g., non-slip) or aesthetics (e.g., embellishments) of the pull.

It should be noted that the composition of the components of the handles is not set in stone, it can be adjusted and customised according to the specific design requirements and the use of the environment. For example, in some special application scenarios, a more complex structural design or the addition of additional functional components may be required to meet specific needs.

How to install the handle

The installation of handles is a seemingly simple but crucial part of home renovation or daily maintenance. A solid and beautiful handle can not only enhance the overall quality of the home, but also bring a convenient experience. We will introduce the installation of handles in detail, including installation steps, precautions, common problems and solutions to help you easily complete the installation of handles.

1. Pre-installation Preparation

Tools and materials: First of all, make sure you have prepared the required tools and materials, including but not limited to screwdriver (choose the appropriate Phillips or one-word screwdriver according to the type of screws), hand drill (if you need to make holes), hole punch, screws, measuring tools (such as tape measure or level), handles and fittings, and so on.

Check the fittings: Before installation, carefully check whether the handle and its fittings are complete and undamaged, especially the screws, nuts and other small parts, so as not to affect the progress of the installation process found missing.

2. Determine the installation position

Measurement and positioning: According to the size of the door or drawer and personal use habits, determine the installation position of the handle. Usually, the handle should be installed in the centre of the door or in a position that is easy to hold. Use measuring tools to accurately measure and mark out the installation holes.

Pay attention to symmetry: For double doors or drawers, make sure that the handles are mounted symmetrically on both sides to enhance the overall aesthetics.

3. Punching and installation

Punching: If there is no pre-drilled hole in the installation location, you need to use a hole punch or hand drill to punch the hole. Pay attention to control the depth of drilling, so as not to damage the internal structure of the door or drawer. At the same time, keep the perpendicularity of the punched holes to ensure that the handle is stable and does not shake after installation.

Install the handle: Place the handle on the mounting holes and make sure the holes are perfectly aligned with the handle’s holes. Then, use a screwdriver to screw the screws into the holes one by one until the handle is tightened on the door or drawer. When tightening the screws, use moderate force to avoid damage or loosening caused by over-tightening.

4. Adjustment and Inspection

Adjust the position: after the installation is completed, check whether the handle is firm without shaking, and adjust its position to ensure that it is parallel to the door or drawer surface or meet the design requirements. If necessary, use a screwdriver to gently adjust the tightness of the screws.

Check the appearance: Check whether there are scratches or stains on the surface of the handle, clean it in time and protect its surface gloss.

5. Precautions

Safe operation: Pay attention to safety during the installation process, avoid using too much force to cause the tool to slip and hurt people or damage the items.

Choose the right screws: Choose the right screws according to the material and thickness of the door or drawer to ensure the solidity of the installation.

Avoid excessive force: Use moderate force when tightening screws to avoid damage or loosening due to over-tightening.

Protect the surface: Protect the surface of the door or drawer from being scratched or damaged during installation.

6. Common problems and solutions

Loose screws: If you find the screws loose, you can use a screwdriver to re-tighten them. If the problem still can’t be solved, the screws may be mismatched or the holes may be damaged, so it is necessary to replace the screws or repair the holes.

Handle wobble: If the handle wobbles after installation, the holes may not be aligned or the screws may not be tightened. Re-adjust the holes and tighten the screws to solve the problem.

Surface scratches: If the surface of the handle is accidentally scratched during the installation process, it can be repaired with a polish that matches the handle material. For serious scratches, it is recommended to contact a professional for treatment.

In conclusion, although the installation of handles may seem simple, it also requires careful operation and attention to detail. By following the above steps and precautions, you will be able to easily complete the installation of handles and enjoy the convenience and aesthetics they bring.

Chapter 5

Why choose us

1000+ Models

At UMAY, we offer over 1000 lever models. Including modern, European, vintage, luxury and minimalist styles. Every lever manufactured by UMAY has a service life of at least 100,000 cycles.

78+ hour salt spray test

Consistent high quality is the basis for UMAY development. We produce a variety of finishes such as chrome, brushed nickel, bronze, and more. Each color can pass 78 hours salt spray test.

Competitive price

Source-direct raw materials, excellent management, fewer mistakes, and 100% control of all processes to achieve cost reductions and efficiencies.

Customized Service

Sourcing door handles for your brand? We’ve got a streamlined process for private door hardware brands! From logos designing, product packaging to even shipping prepping, we got your business covered!

Sourcing Assistant

Looking to source hundreds of different types of door hardware? We offer locks, handles, hinges and so many more! What’s better, we offer free samples for quality distributors!

Commercial Secret

For your new design, we can do 3D samples for you. Factory-owned mold production department, promise customers product’s privacy.

Design Center

Our company doesn’t just offer standard styles of door handles, we also have a team of experienced and creative designers. Our designers are able to create a unique door handle design tailored to your ideas, needs and inspirations, ensuring that it matches your personal style and taste.

Auspicious Cloud Pull Handle

The cloud motif, or “Xiangyun,” is a highly significant symbol of good fortune in traditional Chinese culture, commonly seen in paintings, architecture, carvings, and other forms of art. Its shape is characterized by soft, flowing curves, resembling mist drifting through the air, evoking a sense of expansiveness and tranquility.

The door handle’s main form adopts the flowing lines of the Xiangyun pattern but avoids overly intricate decorations, simplifying it into a modern geometric design. The overall curve resembles a cloud in motion, light and naturally fitting the hand for a comfortable grip. The ends of the handle feature curled details, as if the edges of the cloud are gently rolling, giving the design a dynamic aesthetic. In the details, traditional cloud patterns are engraved on the surface or within the handle, combining both recessed and raised carvings to enhance the visual depth. This approach adds ornamental value while maintaining simplicity.

The designer chose traditional materials such as bronze and brass, combined with wood. The metal part is used to carve the Xiangyun pattern, adding texture, while wood is applied to the area in contact with the hand, bringing a warm tactile experience. This combination of materials not only honors the weight of ancient craftsmanship but also integrates modern comfort into daily life.

This door handle, inspired by the ancient Chinese Xiangyun pattern, is more than a functional tool; it is a work of art that merges traditional culture with modern design. Every action of opening or closing the door creates an invisible connection with historical and cultural heritage.

Ladybower Handle

The design of the Ladybower handle is inspired by the whirlpools that form during the release of flood water from the Lydney Bower Reservoir in the UK, combining the dynamics of the curves of the whirlpools with the static of the lake to create a handle that is both softly textured and hardened.

Arch Handle

China’s arch bridges boast a long history, with typical examples being the Baodai Bridge in Suzhou and the Zhaozhou Bridge in Zhaozhou. They not only occupy an important position in architectural history, but their graceful arched structures also embody the Chinese cultural concepts of “harmony” and “balance.” The structural stability and gentle curves of arch bridges have become the core design inspiration for this door handle.

The most prominent feature of arch bridges is their elegant arched span, which designers have directly transformed into the main shape of the door handle. The arc of the handle echoes the curve of the arch bridge, imparting both a sense of stability and visual balance and beauty to the door handle.

In the design, the complex structure of traditional arch bridges has been simplified into modern geometric shapes while maintaining simple and smooth lines. This not only embodies the minimalist aesthetics of the new Chinese style but also ensures the convenience and visual modernity of the door handle.

By fusing the essence of traditional Chinese arch bridge design with modern design concepts, this Arch New Chinese Style door handle has created a practical work of art with cultural significance. Not only does it embody the elegance and stability of arch bridges in its form, but it also brings a comfortable user experience through material and detail processing. Every time a user engages with this door handle, they not only feel the simplicity and practicality of modern design but also resonate deeply with traditional Chinese culture.

Show us factory

With the interational advanced level of high-precision automatic special equipment and production lines, with leading technology, modem standardized management, from raw material purchase, processing, assembly, finished product testing, each process is standard products.

Determined to innovate new products, to bring customers a better experience we never stops and strives to forge ahead for international famous products. Willing to create brilliant with our customers. Efforts to improve the enterprise’s own management level and brand quality.

Our Certifications

We understand that it is difficult to fully dispel your concerns with only verbal promises. Therefore, we have actively sought and obtained a number of certificates issued by international authorities, such as ISO 9001 quality management system certification, CE safety certification, etc. These certificates are not only the recognition of our product quality, but also a strong proof that our products comply with international safety standards and environmental requirements. These certificates are not only the recognition of our product quality, but also the strong proof that our products comply with international safety standards and environmental protection requirements. If you want to see our certificates, please contact us!

If you want to see our certificates, please contact us!

+86 15358427968

umay@umaylock.com

Customer Satisfaction

Our factory works round the clock to supply our customers with door handle that can be customised to suit their preferences. We take pride in our ability to manufacture on time and provide our customers with the products they require through an efficient production chain. Our technicians are experts in their respective fields and are committed to delivering the products as per the specified delivery schedule. Our focus is on customer satisfaction and we aim to deliver our products according to the specifications provided to us by our customers. Our staff understands that time is important. When we commit to a certain time frame, rest assured that we will deliver.

Check out our customer testimonials below:

Chapter 6

FAQ

Yes, we are pleased to provide free samples.

Yes, we would be delighted to welcome you to visit our factory. We can help you book your flight and hotel, and we will pick you up by car from the stations,

Yes, we can try our best to help you to supply other products for you. While you need to give us the detailed information and specification for the products. We can also help you to inspect your goods, as well as arrange shipping.

We are a company that lives and breathes credit and reputation, and we have been known in the hardware industry for many years. We will not risk damaging our credit and reputation by accepting your deposit. We will keep you informed of the production progress with videos and photos during the production process.

- No, but there are common standards. For example, the backset (distance from door edge to center of the handle hole) is typically 2-3/8" (60mm) or 2-3/4" (70mm). Hole sizes are often 2-1/8" (54mm) in diameter.

- A deadlatch is a spring-loaded latch mechanism that locks automatically when the door is closed. Unlike a simple latch, it resists being forced open, enhancing security.

- A modern door handle features minimalist design, often with clean lines, slim profiles, and finishes like matte black, brushed nickel, or polished chrome.

- European doors often place knobs centrally for aesthetic reasons and because multi-point locking mechanisms align with that position.

Yes. Common types include:

- Lever handles: Operated by pushing down or pulling up.

- Pull handles: Fixed handles for pulling.

- Knob handles: Circular handles that turn to operate.

- Specialty types like privacy, passage, and keyed-entry handles.

- No, compatibility depends on the door's thickness, hole size, and backset.

- Door knob: Rounded and requires turning.

- Door handle (lever): Straight or curved, operates by pushing down or pulling up, easier to use.

- Tighten loose screws or replace stripped ones.

- Align the latch mechanism properly if the handle sticks.

- For mechanical issues, replace internal springs or the entire handle.

No, sizes vary, especially for decorative or modern designs. Measure your door before purchasing a replacement.

Measure:

- Backset (2-3/8" or 2-3/4").

- Door thickness (1-3/8" to 1-3/4" for most residential doors).

- Hole diameter (standard is 2-1/8").

- Yes, for most standard designs. You’ll need a screwdriver and possibly a drill for adjustments.

- Match the backset, hole size, and door thickness with the handle's specifications.

- Matching hinges and handles in finish (e.g., satin nickel or matte black) creates a cohesive look, though it's not mandatory.

- Yes, provided the new handle fits the existing lock mechanism.

- Yes, especially if you’re replacing an existing handle of the same size.

- Through bolts provide extra stability and durability, ideal for high-traffic or heavy doors.

- Remove the old handle by unscrewing it.

- Align the new handle with the existing holes and attach it.

- Test the latch and ensure smooth operation.

Yes, depending on the issue:

- Tighten loose screws or replace missing ones.

- Replace worn or broken internal springs.

- If the handle is beyond repair, consider replacing it entirely.

Yes, but you may need to:

- Drill new holes or enlarge existing ones.

- Match the backset, hole diameter, and door thickness.

- Fill or patch unused holes for aesthetics.

- Yes, especially if the door already has the correct holes. Basic tools like a screwdriver are usually sufficient.

- Yes, as long as the frame is in good condition and the new door aligns with the existing hinges and latch positions.

- Yes. Most handles can be removed by unscrewing them from the door. For concealed screws, you may need to remove a cover plate first.

- Remove the old handle.

- Measure the existing holes and backset.

- Install the new handle, aligning it with the latch mechanism.

- Secure it with screws and test for proper operation.

Measure:

- Backset: Distance from the door edge to the center of the hole (usually 2-3/8" or 2-3/4").

- Hole diameter: Standard is 2-1/8".

- Door thickness: Common is 1-3/8" to 1-3/4".

- Yes, but older doors may have non-standard hole sizes. You might need to modify the door for modern knobs.

- Ideally, hinges and knobs should have complementary finishes (e.g., both in brushed nickel). However, matching is optional and based on personal preference.

- Many are standardized, but older or custom doors may require adjustments to fit new knobs.

- Identify the brand and model of your existing hardware.

- Match the style, finish, and dimensions.

- Bring the old handle or knob to a hardware store for comparison.

- This is a release hole, used to unlock privacy knobs (e.g., bathroom doors) with a pin or tool.

- Yes, as long as they are compatible with the door’s thickness and the latch mechanism. Mixing finishes or styles can be a design choice.

- Check the backset, hole diameter, and door thickness. Most product descriptions include compatibility details.

- Follow building codes for accessibility (e.g., lever handles are often required for commercial spaces).

- Ensure proper alignment and secure installation.

- Match the style to the door and room decor.

- No. Compatibility depends on size, latch type, and door specifications.

- Pull handles are fixed handles designed to allow a user to pull a door open. They don’t engage a latch or locking mechanism but are purely for gripping and pulling.

- Ease of Use: Ergonomic and require less precision than knobs or levers.

- Durability: Simple construction makes them long-lasting.

- Design Versatility: Suitable for modern and traditional aesthetics.

- Application Range: Can be used on large, heavy, or glass doors where extra leverage is needed.

- Mark the Location: Measure and mark the placement points on the door.

- Drill Holes: Drill holes through the door or surface as needed.

- Attach the Handle: Secure the handle using screws or bolts provided.

- Check Alignment: Ensure the handle is level and properly tightened.

- The pull side is the side where the door opens toward the user. Pull handles are typically installed on this side to allow easy operation.

- On front doors, pull handles are often paired with a deadbolt or latch mechanism operated separately. The handle provides grip for pulling the door open after unlocking.

- Lever Handles: Operated by pushing down or lifting.

- Knobs: Turnable, often for latching mechanisms.

- Pull Handles: Fixed for pulling only.

- Flush Handles: Recessed into the door for a sleek look.

- Push-Pull Handles: Allow doors to open with either pushing or pulling without turning.

These handles are designed to allow opening by pushing or pulling without requiring a turning motion. They often use spring-loaded mechanisms for self-alignment.

- Cabinet Handles: Smaller and often require a more delicate grip.

- Pulls: Larger, designed for heavier or larger doors, and provide better leverage.

- Knobs: Aesthetic and compact but require twisting, which might be harder for people with limited dexterity.

- Pulls: More ergonomic and versatile, especially for larger doors.

- Lever handles are user-friendly, accessible, and easy to operate with minimal effort, making them suitable for homes with children or elderly individuals.

- Pull handles are used to open doors, drawers, or cabinets, providing a simple and effective grip.

- Simplified operation.

- Stylish and versatile design options.

- Robust and reliable for heavy or frequently used doors.

- Push-pull handles eliminate the need to turn or rotate. Pushing activates the latch mechanism in one direction, while pulling operates it in the other, making them ideal for high-traffic or modern applications.

We’d like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right stainless steel door handles you want.

+86 15358427968

umay@umaylock.com