Introduction

When choosing a mechanical door lock, durability is a key concern. A lock that fails prematurely can lead to security risks, costly replacements, and customer dissatisfaction. One of the most reliable ways to ensure a lock’s longevity is through cycle testing. This rigorous process simulates real-world usage, measuring a lock’s ability to withstand repeated operation over time. But what exactly is cycle testing, and why is it crucial for selecting high-quality door locks? Let’s dive in.

What is Door Lock Cycle Testing?

Cycle testing, also known as operational or endurance testing, is a standardized method used to evaluate the durability of mechanical door locks. During this test, a lock is repeatedly engaged and disengaged—often tens of thousands, or even millions, of times—to simulate years of use. This helps manufacturers and buyers assess whether a lock can maintain its function and integrity under continuous operation.

Several international organizations have established guidelines for cycle testing. For example, the American National Standards Institute (ANSI) and the Builders Hardware Manufacturers Association (BHMA) outline specific performance requirements for different lock grades (ANSI/BHMA standards). Similarly, the European Norm (EN) standards provide benchmarks for locks sold in the EU (EN 12209)

Why is Cycle Testing Important?

A lock that hasn’t undergone proper cycle testing may fail prematurely, leading to security breaches, operational issues, and increased maintenance costs. Here’s why cycle testing is essential:

- Ensures Durability: High-cycle testing verifies that a lock can withstand continuous use in high-traffic areas, such as commercial buildings, hotels, and hospitals.

- Prevents Unexpected Failures: A lock that malfunctions after a short period can cause significant inconvenience and security risks.

- Supports Compliance: Many building codes and safety regulations require locks to meet specific endurance standards.

- Cost Savings: Investing in a thoroughly tested lock reduces the long-term cost of replacements and repairs.

- Better Customer Satisfaction: End-users expect locks to function smoothly over time; testing ensures the product meets their expectations.

Industry Standards for Cycle Testing

Different regions have their own standards for lock durability, which dictate the minimum cycles a lock must endure before failure:

- ANSI/BHMA Grading

- Grade 1: 1,000,000 cycles (highest durability, used in commercial applications)

- Grade 2: 800,000 cycles (mid-range durability)

- Grade 3: 200,000 cycles (residential-grade locks)

- European Standard EN 12209

- The standard defines mechanical strength, durability, and corrosion resistance.

- Requires locks to undergo at least 200,000 cycles for general applications.

- ISO 14451 (International Standard for Mechanical Locks)

- Sets global benchmarks for performance, ensuring consistency across different markets.

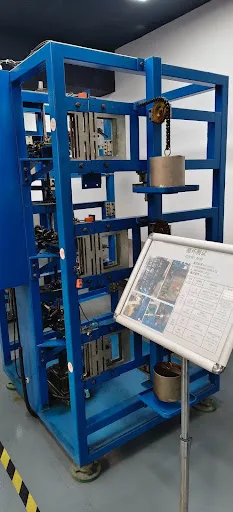

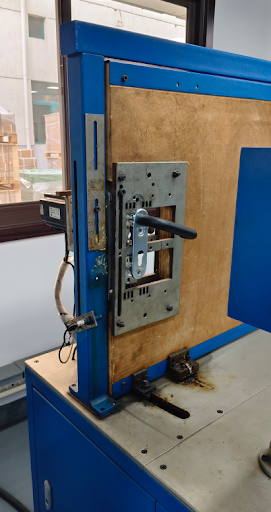

How We Conduct Cycle Testing

To ensure our mechanical locks meet the highest industry standards, we perform rigorous cycle testing using specialized testing equipment. Our process includes:

- Automated Testing Machines: These machines repeatedly lock and unlock the mechanism under controlled conditions.

- Realistic Load Conditions: We apply pressure to simulate actual usage scenarios, including forceful closing and improper handling.

- Environmental Stress Testing: Locks are exposed to extreme temperatures, humidity, and corrosion to assess their durability in different conditions.

- Comprehensive Reporting: Each lock is evaluated for wear and tear, with detailed reports generated to ensure compliance with industry benchmarks.

Choosing a High-Quality Mechanical Door Lock

When selecting a lock, consider the following factors to ensure long-term performance:

- Look for Certified Products: Ensure the lock meets ANSI/BHMA, EN, or ISO standards.

- Check Cycle Ratings: Higher cycle counts indicate better durability.

- Material Quality: Solid brass, stainless steel, or zinc alloy locks tend to last longer.

- Corrosion Resistance: Look for finishes that withstand rust and environmental damage.

- Manufacturer Reputation: Choose locks from trusted brands with a track record of quality and reliability.

Conclusion

A cycle test is a fundamental quality assurance measure for mortise locks, ensuring durability and reliability under prolonged use. Buyers should prioritize locks that meet industry standards and have undergone extensive testing to guarantee performance in demanding environments. Investing in a well-tested mortise lock not only enhances security but also reduces maintenance costs and prolongs the lock’s service life.

Our Commitment to Quality

Our SUZHOU UMAY ensures that all our mortise locks undergo strict and professional cycle testing, guaranteeing durability and reliability. We stand behind every order, providing you with locks that meet the highest industry standards for long-term security and performance.

Share This Story, Choose Your Platform!