Choosing the right type of door lock is essential for both security and installation efficiency. Two of the most common options in the residential and light commercial hardware market are tubular locks and cylindrical locks. While they may look similar, their internal mechanisms and use cases are quite different.

In this article, we’ll break down the key differences between the two and help you decide which is best for your project. As a manufacturer and global exporter of door hardware with over 20 years of experience, Umay supplies both tubular and cylindrical locksets to door manufacturers, importers, and retail chains across the UK, Middle East, and Europe.

What are Tubular Locks?

Tubular locks, also known as tubular latches, are designed for ease of installation and quick operation. They are especially popular in residential interior doors.

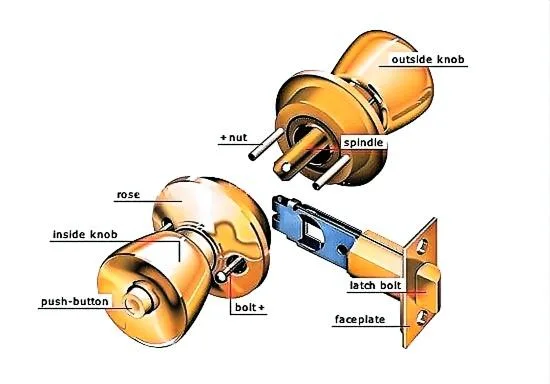

Structure & Mechanism

A tubular lock features a cylindrical latch body with a spring-loaded latch bolt. It usually doesn’t have a complex internal locking mechanism. For added security, a separate round cylinder lock can be combined when needed.

Easy Two-Hole Installation

Only two holes are required for installation:

- A 2⅛” (54 mm) hole in the door face for the knob or lever.

- A 1″ (25 mm) hole on the door edge for the latch bolt.

This makes it a cost-effective and time-saving solution for home renovations and commercial fit-outs.

Ideal Applications

- Interior bedroom doors

- Bathrooms and closets

- Light-use commercial doors

It’s a popular choice due to its simplicity and low cost of labor.

Specifications

- Backset Options: 60 mm, 70 mm, 75 mm, 80 mm

- Compatible Door Thickness: 35 mm–45 mm standard (custom options available)

Knob/Handle Diameter: Typically 50–60 mm

Common Types

- Passage Knob – No locking, just a latch (ideal for hallways)

- Privacy Knob – Push-button lock from inside (used in bathrooms)

- Keyed Knob – Basic key entry for interior security

What are Cylindrical Locks?

Cylindrical locks are a step up in terms of security and mechanism, commonly used on exterior and high-traffic interior doors.

Installation Method

Like tubular locks, cylindrical locks also use two holes:

- A 2⅛” (54 mm) bore for the knob or lever

- A 1″ (25 mm) hole on the edge for the latch or deadbolt

But the key difference lies in the internal chassis and locking mechanism, which is more robust and suitable for commercial use.

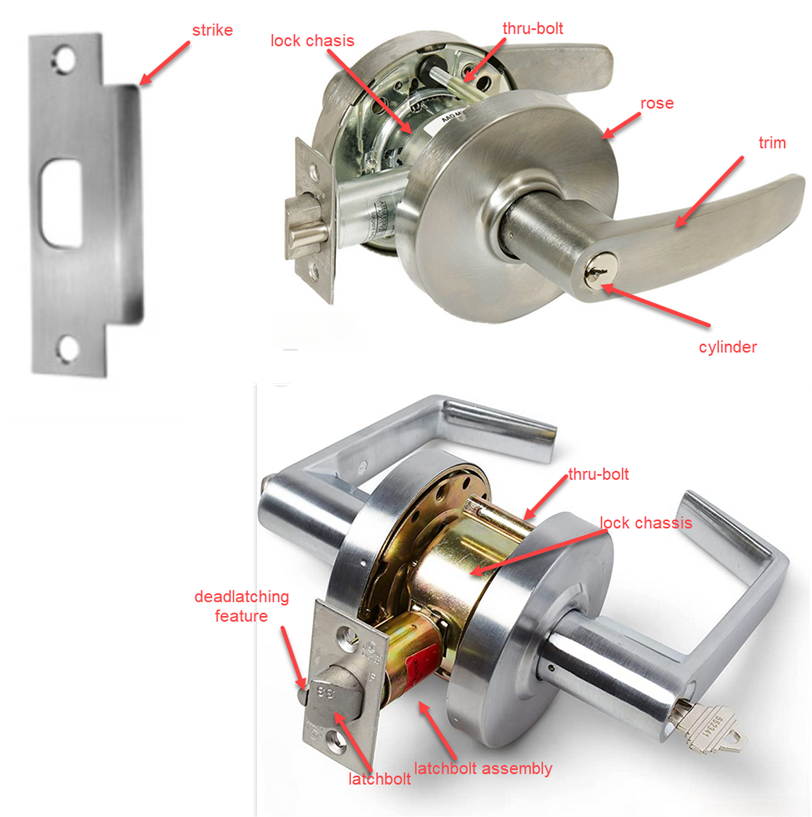

Key Components

- Outside Lever/Knob: Usually includes a keyhole for external access

- Inside Lever/Knob: Often has a thumb turn or push-button for locking

- Latch Bolt: Spring-loaded and retractable

- Cylinder: Houses the keyed lock; can support master key systems

- Chassis: The internal structure that connects everything

These locks are often ANSI or BHMA certified. You can explore standards like ANSI/BHMA A156.2 for commercial locksets.

Ideal Applications

- Office entry doors

- Apartment units

- School and hospital doors

Medium-security commercial settings

Key Differences Between Tubular and Cylindrical Locks

Feature | Tubular Lock | Cylindrical Lock |

Installation | Simple; two holes | Same, but chassis more complex |

Mechanism | Spring latch, basic structure | Advanced with replaceable core |

Security | Basic to moderate | Moderate to high |

Applications | Interior doors | Exterior and high-traffic doors |

Cost | Lower | Higher |

Lock Options | Passage, privacy, keyed knob | Full locking functions with cylinders |

Tubular Locks feature a latch mechanism where the lock bolt retraction system is integrated directly into the latch body itself. A square or half-moon-shaped spindle extension from the outer handle fits through the latch mechanism, enabling the operation. Once assembled, the inside and outside knobs or levers are mechanically connected via this extension, moving together as a single unit.

This design makes tubular locks relatively simple and cost-effective, ideal for light-duty interior applications. However, they offer limited configuration options and locking functions due to the shared spindle design and compact internal structure.

Cylindrical Locks, in contrast, house the retraction mechanism within the main chassis rather than in the latch. The latch serves primarily as a connector and is structurally simpler. Inside and outside spindles operate independently, allowing for more advanced functionality. For example, cylindrical locks can support various commercial-grade functions such as storeroom, classroom, passage, privacy, and entry configurations.

In many cases, the exterior lever can be “clutched” — it rotates freely without engaging the latch — a useful feature for enhanced security and wear resistance.

Moreover, cylindrical locks use more robust materials. The chassis components, rosettes, and mounting plates are typically made from thicker steel, and both the interior and exterior bushings require higher precision machining to ensure reliable spindle alignment. This durability makes them well-suited for high-traffic or commercial environments.

Because the latch retraction mechanism is enclosed within the outer chassis and protected by a cylindrical sleeve, cylindrical locks are easier to manufacture to UL fire-rated standards, a critical requirement in many building codes.

Tubular locks are perfect when speed and budget matter. Cylindrical locks are better when security and durability are a priority.

Why Choose Umay for Your Door Locks?

At Umay, we specialize in door locks, handles, hinges, viewers, and closers designed for both residential and commercial applications. We manufacture high-quality tubular and cylindrical locks that meet international specifications and customer demands.

Our clients include:

- Door manufacturers seeking OEM solutions

- Regional hardware importers

- Procurement managers for retail chains and DIY supermarkets

We provide customization for backset, finish, knob shape, and lock cylinder systems, including master key options for hotels and apartment buildings.

Explore our full range of mechanical door locks and contact us for bulk orders or catalog requests.

Final Thoughts

The choice between tubular and cylindrical locks depends on where and how the lock will be used. For indoor privacy, tubular locks are ideal. For areas needing more robust security, cylindrical locks are the better fit.

No matter your needs, Umay has the right solution. Let our 20+ years of global sales experience in door hardware work for you. We’re not just selling locks — we’re securing value.

Share This Story, Choose Your Platform!